Why White Cedar

What is White Cedar?

What is White Cedar?

White cedar is an evergreen or coniferous tree, and is a softwood, in contrast to trees like maple and oak, which are deciduous and called hardwoods.

Its Latin name is “thuja occidentalis” – other names are eastern white cedar, northern white cedar, arborvitae and eastern arborvitae.

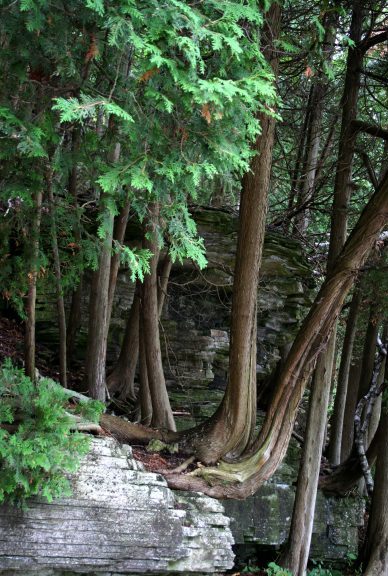

White cedar is very common in the northeastern U.S.A., southern Ontario, and northern Ontario up as high as James Bay. It grows mainly in rocky and wet areas, and has a wide fibrous root system which allows it to cling to rocky difficult areas where hardwoods cannot grow. It is a medium size tree, growing to a size of roughly 50 feet when mature.

It contains natural oils which protect against mould, temperature variations, moisture and insects. Its name “arborvitae” means “tree of life”- appropriate since its flattened leaves are eaten in the winter by wildlife such as deer, and its protective oils have made it useful for centuries in the production of items which must resist decay even when in contact with moisture, and outdoors in extreme temperatures – items such as logs for cabins, poles, posts, rails for fences, shingles for roofs, saunas, decks, docks, etc. It is no accident that many barns were made from cedar boards, and are still standing many decades later.

Advantages of White Cedar

- Its special oils make it resistant to rot and insects, even in harsh outdoor conditions of moisture and low temperatures. It is considered one of the most decay resistant trees in North America.

- Its natural resistance to decay makes it highly desirable in environmentally sensitive areas such as waterfronts where the chemicals in pressure treated lumber would cause concern.

- It dries relatively quickly, compared to many other woods. Generally air-drying is sufficient, whereas many woods such as maple, oak and cherry must be kiln dried. In addition, as cedar dries, it is very stable, and resists warping and shrinking better than most species.

- It cuts easily, with minimal cracking and splitting.

- It is very easy to work with, since it cuts so easily. You can use screws or nails directly in the wood, rather than drilling an initial hole as you need to with harder woods such as oak.

- It is one of the lightest Canadian wood species, making it easy to carry and handle. Its lightness is due to many microscopic air pockets, which help give it an insulating value. Rooms lined with white cedar paneling will feel warmer than those which are not. The R value of white cedar exceeds that of red cedar or pine.

- It is an attractive wood, with great variations in grain, patterns and knots.

- Its neutral colour takes stains or paint easily.

- White cedar costs less than red cedar.

White Cedar Compared to Red Cedar

- White cedar is known as eastern white cedar since it is found primarily in the eastern half of North America. Red Cedar is known as western red cedar since it is found in the western half of North America

- In our area, white cedar is consistently less expensive than red cedar, since white cedar is obtained locally, whereas red cedar must be shipped across the continent. In an era where gasoline prices are very unstable, and seem to spike frequently, the cost of transportation is significant.

- Both woods contain oils which protect them against rot and insects. Some studies have shown that posts made of eastern white cedar outlast posts made of western red cedar by as much as 11 years.

- Both woods have a pleasant characteristic odour – brides used to store their precious fabrics in “hope chests” made of cedar – their possessions smelled good, and were totally safe from moths and other insects.

- Both woods are very light: white cedar has a density of 0.31 g/cm3, and red cedar has a density of 0.47 g/cm3. This is less than half the density of water.

- Both woods have a fairly straight grain and are easy to work with.

- White cedar and red cedar are not noted as particularly strong woods. Beams in barns would not be made of cedar, but stronger woods such as ash, oak and maple. Red cedar is slightly stronger than white cedar.

- White cedar trees tend to be smaller than red cedar trees (50 feet compared to 200 feet). This means that white cedar tends to have more knots than red cedar, since the knots form where side branches come out of the trunk. This gives white cedar more “character”, but also requires vigilance in making sure that the knots in the boards are solid and attractive, and do not diminish the appearance and functionality of the board. It also means that it is difficult to obtain very wide white cedar boards, since the tree trunks are smaller. A 16 inch wide white cedar board would be very difficult to obtain, and hence quite expensive.

- Both woods are very attractive.

- Both woods can be left to weather naturally, or treated with a huge variety of preservatives and stains. However, white cedar weathers to an attractive silver grey, whereas red cedar tends to turn black as it weathers.

A Word About Knots

Since white cedar trees are comparatively short trees (50 feet), white cedar lumber does contain knots, produced when the branches form off the main trunk of the tree. These knots add character to the wood, and make it more interesting than plain (“clear”) lumber. Toleration for the number and type of knots is a very individual taste. Most people would prefer to avoid knots that can easily fall out, leaving holes behind.

This is the standard adopted by Scouten White Cedar – boards with unstable knots or holes are rejected – either discarded or sold as #2 lumber at a reduced price. Even if the knots are stable, the board is rejected if the number or size of the knots is deemed excessive.

Using White Cedar Is Environmentally Friendly

- The manufacture of artificial materials for decks and fences requires the consumption of materials and energy, whereas wood is provided by Mother Nature.

- Wood is 100% biodegradable, in contrast to the artificial materials offered for sale for decks and fences – materials which will likely end up in landfills.

- White cedar contains natural oils which resist insects and decay, and is much more desirable in waterfront areas where the chemicals in pressure treated lumber might be cause for concern. Many people are also concerned about their children being exposed to the chemicals in pressure treated wood as they walk on decks in their bare feet.

- A natural material such as white cedar fits in better with the natural environment around a cottage or in a backyard, in contrast to artificial materials.

- White cedar is very plentiful, being found in great quantities in the northeastern U.S.A., and across much of Ontario up as high as James Bay. It is definitely not a threatened species.

- Buying white cedar from local sources is in keeping with the broadening desire of people to buy locally. Compared with shipping red cedar clear across Canada, much less gasoline is consumed in bringing white cedar lumber to your doorstep, and hence much less carbon dioxide is emitted to the atmosphere from the burning of the gasoline. This reduces the production of the gases which are causing the greenhouse effect, and possibly affecting our climate. Buying local white cedar also produces more local jobs, as the trees are cut, transported and milled.

- There are very few waste products from the production of cedar lumber from logs. The unused bark and edge pieces of cedar, known as slab, can be used as kindling or even insulation for underground pipes. The shavings from planing can be used for bedding for horses. The cedar sawdust from the cutting of the logs can also be used for bedding. Wood not suitable for boards can be used for kindling or cut up for mulch for flower beds.

To Coat or Not To Coat Your Cedar Products

Both white and red cedar can be left to age naturally, without coats of preservatives. Because of their natural oils, both will last for a number of years, despite extremes of moisture and temperature. It is certainly the easiest way to go. However, the wood will change colour, and it will not last as long as wood that has been coated with preservative.

The major problems are sun and water. Water will soak into unprotected wood, and the alternating expansion and contraction as the water freezes will damage the wood fibres, accelerating the decay process. This process happens more slowly with cedar than with other woods such as spruce or maple etc, but it still happens, and decreases the useful life of the wood. You can see the effect of the water and the sun’s ultraviolet rays by looking at an old barn and comparing the wood under the roof overhang (protected from the rain and sun) with the wood further down the sides and more exposed to water and sun.

If you choose to coat your white cedar, consider the following points:

- You will be preserving the beautiful natural character of the cedar for years to come, character which will be far less visible if the wood weathers naturally.

- Investigate thoroughly the possible choices of stains, paints and preservatives. There is a huge variety available. Ask at your favorite home store, ask your neighbours who have decks you like, search the Internet, and consult sources like “Consumer Reports”, a magazine which has done a number of studies comparing various deck finishes. You should also investigate the VOC content of the stains you are considering. This refers to the “Volatile Organic Compounds”, which cause noticeable odours, can cause health problems, and are highest in oil-based paints and stains. New legislation restricting the VOC content has resulted in many new water-based products becoming available, and also the reformulation of stains that have been available for years.

- Sun and water are the major enemies. Look for products which contain materials that protect against ultraviolet light, and minimize absorption of water.

- Transparent coatings show the wood the best, but offer the least protection against the sun. Semi-transparent coatings offer more protection, but let some of the grain show through. Opaque coatings offer the most protection, but let none of the natural wood show through.

- Many dozens of different colours are available.

- Realize that some products that protect against water do not protect against the sun, and the wood will still turn gray.

- Avoid products that leave a surface coating on the wood, like varnish or urethane. Over time, the wood will still absorb some water, and this will result in ugly cracking and peeling of the surface layer. Look instead for products that penetrate the wood.

- Most penetrating products need recoating after a period of time – ranging from 2 years to 9 years depending on the product and the surface to be coated. Decks experience the harshest conditions, since they are exposed to the “triple whammy” of lots of sun exposure, exposure to rain and snow, often for months at a time, and finally shoed feet walking on them! Follow the product instructions exactly. In general, a pressure sprayer will remove any gray colour or moss buildup, and the new coat can be put on the thoroughly dried surface with a roller. Recoating is not a terrible job, compared with dealing with peeling paint.

- To judge if re-coating is necessary, simply pour water onto the deck. If it beads and stays on the surface, the protective coating is still good. If the water soaks into the wood, it is time for another coat.

- Most products suggest pre-sanding with 80 grit sandpaper before coating. This lets the preservative soak into the wood and preserve it much better. Often lumber has a mill-glaze on the surface. This is a smooth shiny surface created by the compression of the wood as it goes through the planer. This surface will reduce the ability of the preservative to penetrate the wood, and could even result in the preservative being washed off by the rain.

Overall advice for a beautiful white cedar deck stain or coat:

- Do some thorough research.

- Try the liquids you are considering on small samples of cedar so you know what the final appearance will be.

- Read the label carefully and follow the instructions.